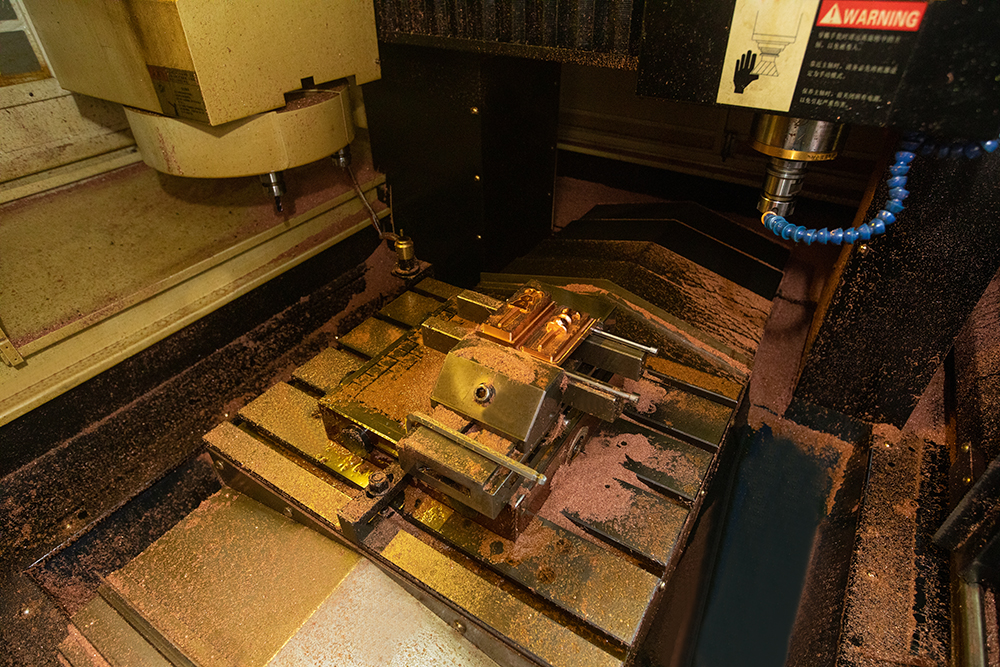

Precision

manufacturing at its best

Tooling + Mold Building

This complex and precise process determines the manufacturability, the lifecycle and the costs of each product. Plastic injection molds are an important asset and regular maintenance is important for longevity of the mold and the quality of the parts it produces. At Victoria, we manage our plastic injection molds with an elaborate process which includes daily preventive maintenance, regular mold inspection as well and minor and major maintenance whenever needed. This is to ensure that the lifespan of the molds are extended for as long as possible.

- 2-plates mold

- 3-plates mold

- hot sprue mold

- hot runner mold

Materials Selection + Prototyping

At Victoria, we pride ourselves for having extensive injection molded plastic material experience. As such, we are able to work closely with our resin supplies to ensure that you get the best material for your product at the best price. Apart from that, our project engineers are very involved in determining what materials, or additives or special coloring is required for the development of your product. The thermoplastic resins that we manufacture product from includes: Polypropylene(PP), Low and high density polyethylene(LDPE + HDPE), High Impact Polystyrene(HIPS), Acrylonitrile Butadiene Styrene(ABS), Polyvinyl Chloride(PVC), Ethylene Vinyl Acetate(EVA) and Resin(K).

Contract Manufacturing

Victoria is an OEM manufacturing company specializing in plastic injection and blow molding. We approach every order with globally recognized quality standards, with trusted quality inspection system, from material warehousing, to quality inspection when manufacturing, to quality control of semi-finished products and to quality assurance of finished goods. We strive to ensure that the products we produce for you will meet your needs.

We believe our expertise, experience and efficiency will help you achieve your production goals.